DMS 3 & 5 Axis

Diversified Machine Systems DMS is a manufacturer of 3-axis and 5-axis CNC routers out of Colorado. Ballscrew Guys are specialists in repairing and refurbishing the Bosch Rexroth ball screws and motion system components DMS uses. These machines are quite common in the fabrication of wind turbine blade components.

We have extensive experience restoring accuracy and function to both the X Axis Table, Y-Axis Gantry, and Z-Axis ball screws on the Diversified Machine Systems CNC routers. We also can refurbish or replace the Bosch Rexroth linear way guide sliders and rails. Our skilled technicians can refurbish realign a machine axis of your machine in less than one production shift.

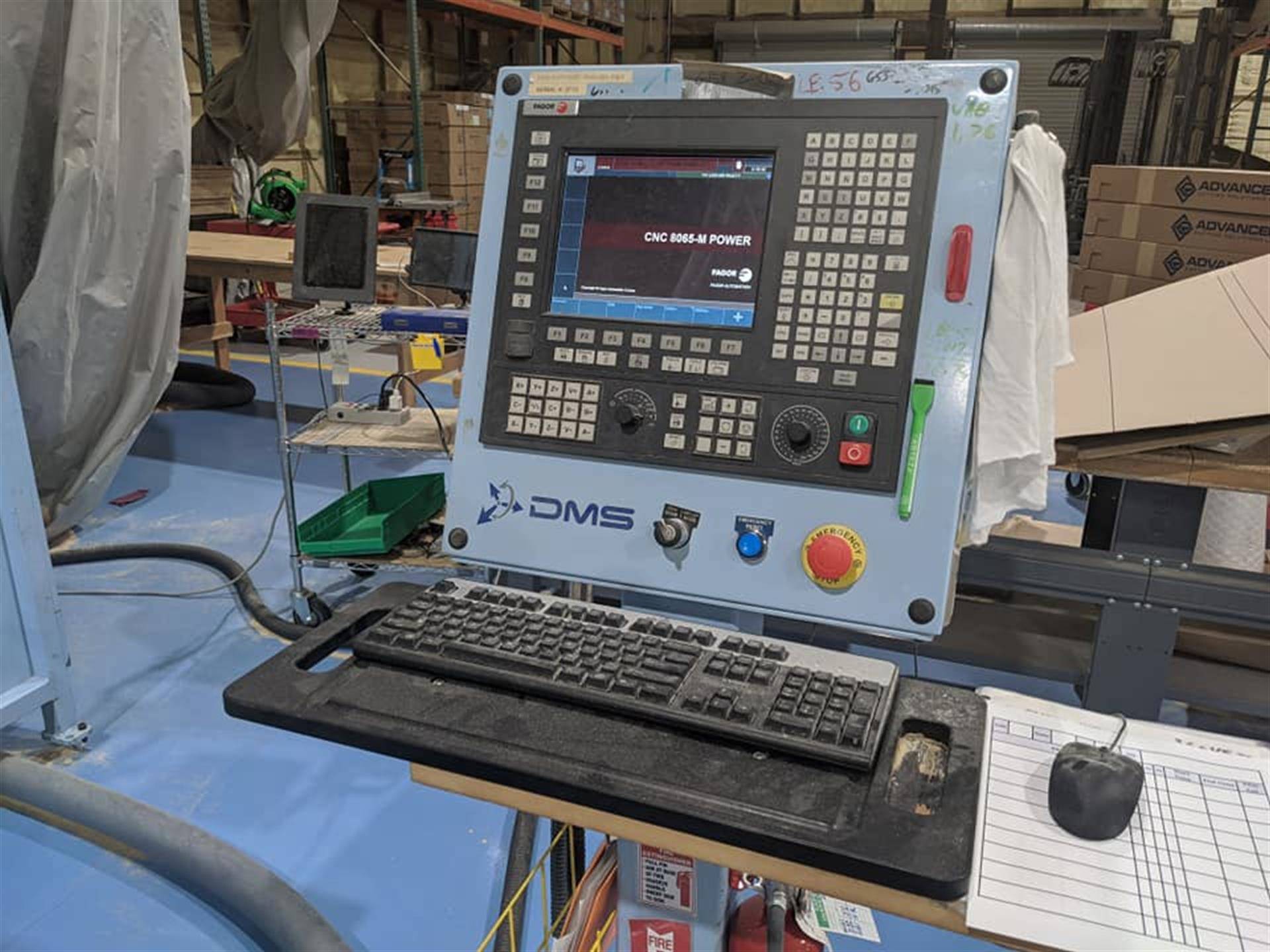

Diversified Machine Systems use Fagor automation control software as well as Fagor motors and drive systems. After service to the Bosch Rexroth ball screws in the machine, the machine axis serviced will require rehoming in the control software.

Notice the giant exposed Y-Axis gantry. The top Y-axis cover has been removed for cleaning and service. Although there is a protective cover, dust and debris from the cutting process will migrate into the bearing systems. It is critical that these are kept clean regularly. The Diversified Machine Systems DMS Routers need regular, under the covers inspection and cleaning for reliable function. Dust and debris being the material most likely to cause failure in your Bosch Rexroth ball screw assemblies and linear way guide systems.

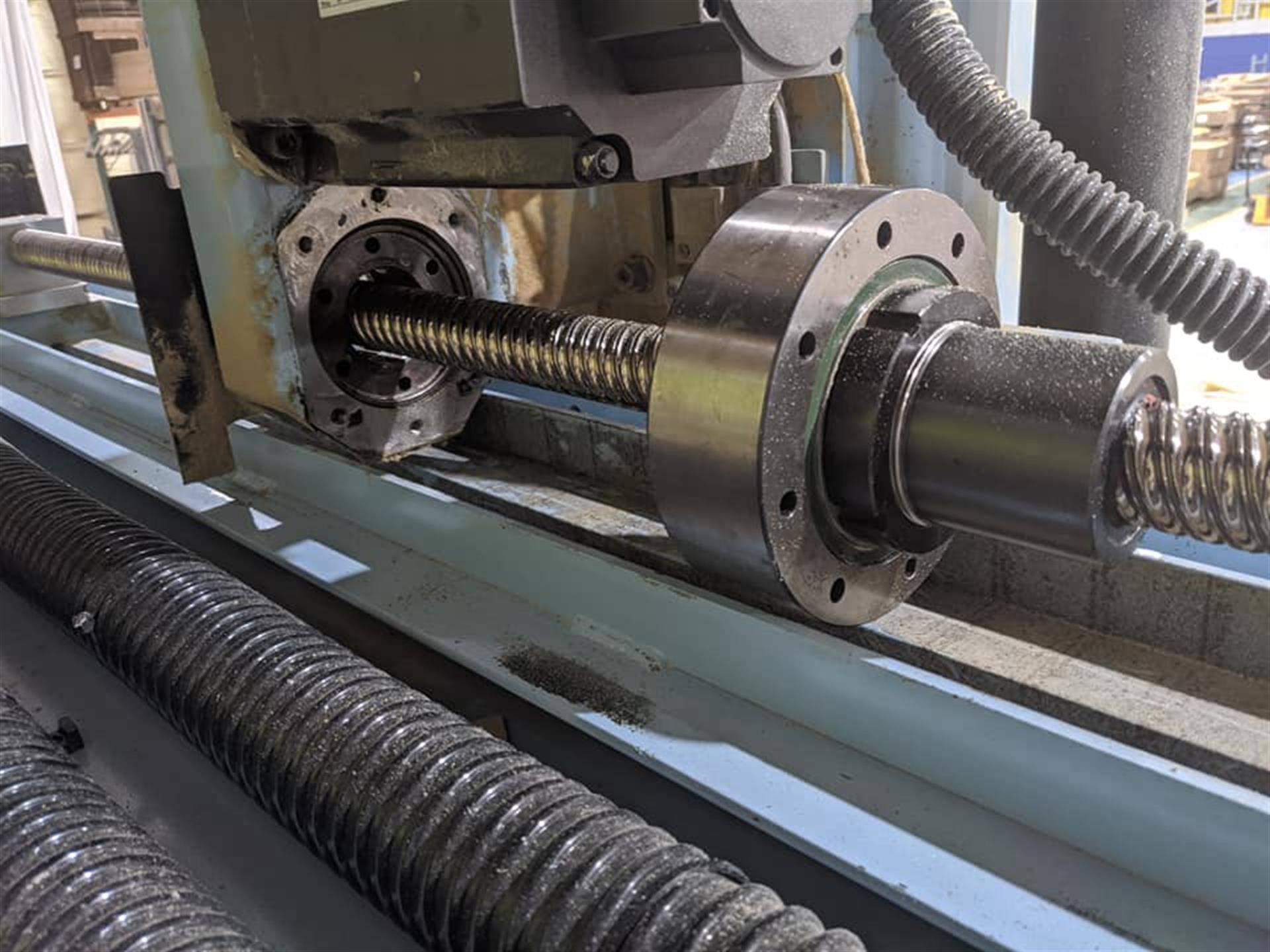

Image taken from on top of a Diversified Machine Systems DMS CNC Router. The protective bellows cover has been removed, exposing the machine head yoke which runs on top of the machine gantry. This Y-Axis is moved back and forth with Bosch Rexroth ball screw with an INA type rotation bearing. On this style of ball nut, the INA rotation bearing is attached to the Y-Axis yoke. The Axis drive is in the form of a belt which spins the ball nut within the rotation bearing. The only provision for lubrication on this style of ball nut is through the rotation bearing. In this INA assembly there are two small 3mm holes which passively leak lubrication into the ball nut. When these small holes get clogged, the ball screw will want to lock up and fail. It is critical to address this issue prior to ball screw failure. We can still repair ball screw assemblies which have undergone full failure but they require more time, materials, and man hours to refurbish.

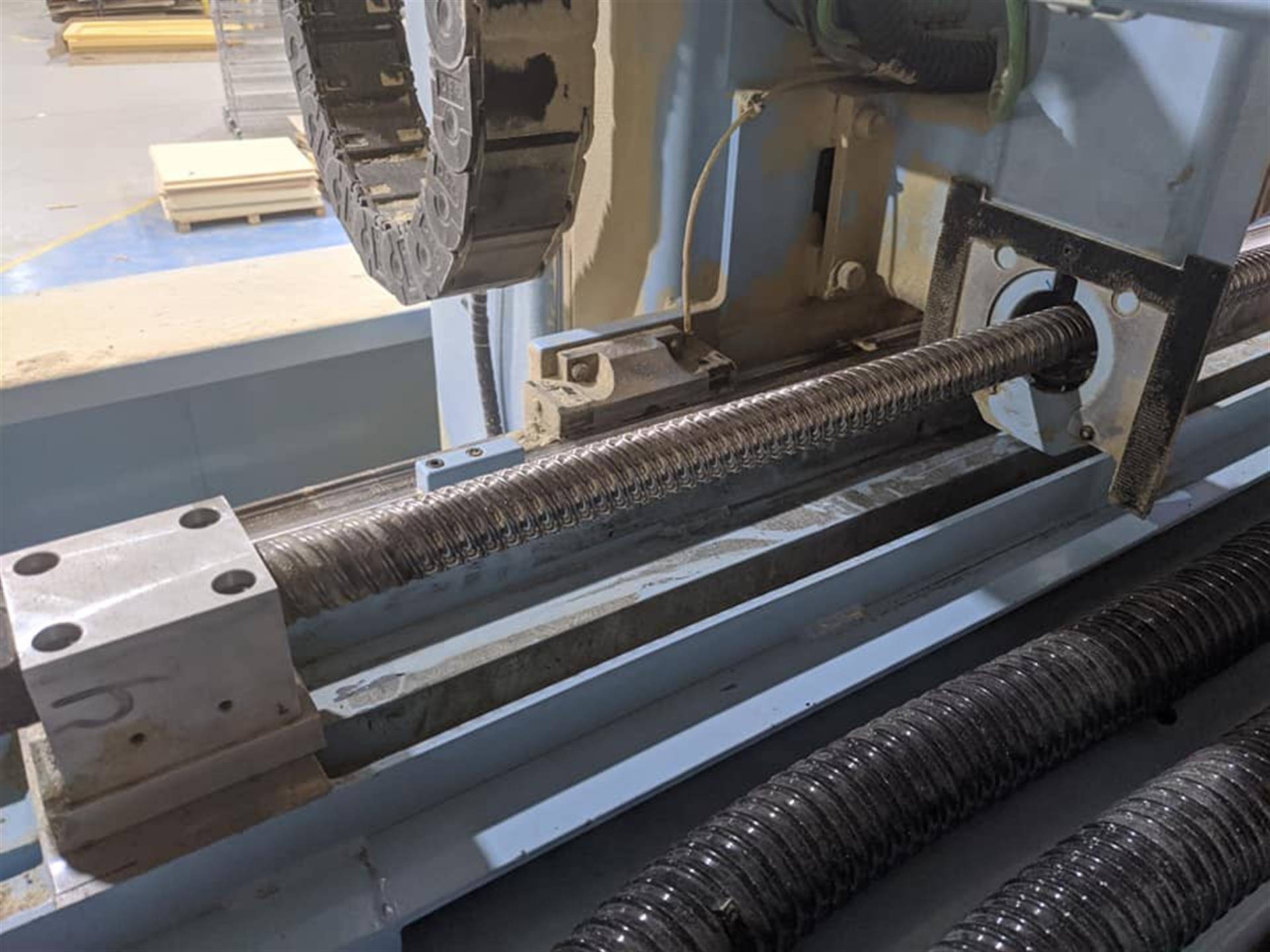

Another Image taken from refurbishment of a Diversified Machine Systems DMS CNC 5-axis Router. This one shows the Bosch Rexroth ball screw as it mounts to an aluminum block on the machine. On the very edge of this assembly is a large hex bolt used to establish and control ball screw tension on the axis. Essentially, the ball screw has to be stretched between to end points to maintain a proper operations tension. It needs to have some flex but still remain tight to minimize vibration. This system is quite common in all CNC applications of the Bosch Rexroth ball screw utilizing the INA rotation bearing system. On a side note, please notice the lack of alignment pin holes in the block. We mention this, because it is easy to remove and reinstall a ball screw on your DMS router, and have it misaligned. Then, when coupled with improper ball screw tension, it can prematurely wear out or destroy even a new ball screw. If you have been chewing through ball screws on your DMS system, this needs to be addressed. We are happy to show your maintenance personnel how to align and maintain ball screws.

This is a Bosch Rexroth ball screw on the Y-Axis gantry of a Diversified Machine Systems router. The ball screw locked up because sawdust migrated into the ball nut restricting the flow of ball bearings and lubricant. When this type of ball screw fails, it destroys plastic ball bearing recirculation scoop inserts. The ball bearings then seize in the ball nut, often breaking or shearing the inserts before shearing the screw. Fortunately the Bosch Rexroth ball nuts ride on one of four machine tracks which means it is possible to rebuild your ball nut by reorienting it to run on an undamaged track. The old damage still needs to be filed and sanded out to be sure the ball screw assembly moves without snag across the damaged section. You can see a small section where the screw shaft is damaged in the photo above. It is critical that detailed inspection of the ball screw be made after this kind of failure.